A visit to NMA in April showed this problem, the E had moved outwards by 3 to 4mm.

Clearly this had to be fixed.

Cristofoli, who did all the water jet cutting of it, thankfully, still had the 3d files so, kindly, and FOC made me two new ones, I asked for one to be 0.5mm smaller all round, just as well as it turned out.

I did a lot of behind the scenes work prior to heading off to NMA, just the paperwork alone is some days work, COSHH data sheets for all chemicals, a full risk assessment etc etc. Eventually it was all on file at NMA and we agreed a date for the work.

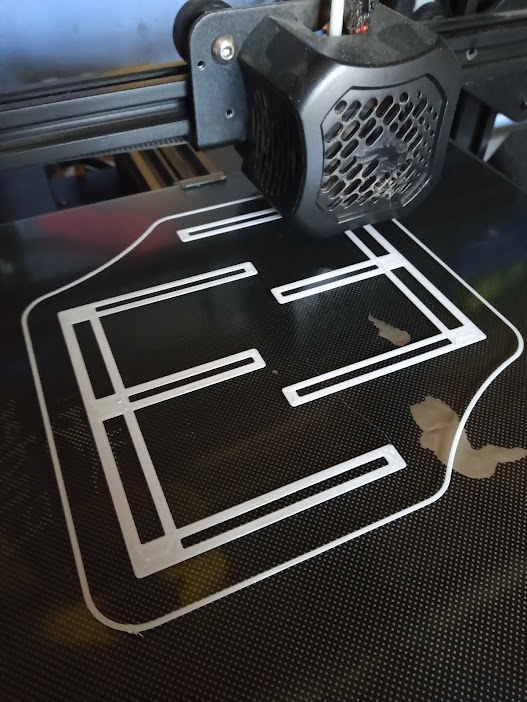

I knew the new and the old E’s were not as thick as the black granite they are set into, so drew and 3d printed a heap of shims in PLA plastic, I also soaked one for several days to be sure they weren’t water absorbent, some plastics are, a surprising one is Perspex which absorbs water to 9% of volume, just as an example.

- Here’s my printer making one of the shims, I made 30 or so from 0.35mm thick to 5mm thick. The slots are for glue to pass through them to the SS backplate.

- The new E’s

- Kit prepared, big clamp seen later

I also bought the correct glue from my local marine adhesives supplier, Marine Industrial. This is a very high quality, and very expensive epoxy, seen in the background of the pic above.

Eventually all the balls were in a row so off Nick and I set in my motorhome to NMA to do the work. We met with the grounds manager I’d been dealing with by email, and got him to agree to the MH being parked on site for the work duration, this was an enormous help to us. We night stopped in a local pub cark park (aka Pubstops in MH terms) so no costs incurred there.

Rather than boring everyone with every tiny detail, the pics below should be self explanatory:-

The second of these pics shows the problem, unbeknown to me the guys at Cristofoli had made a “shim” of MDF to set the E flush with the black granite, Had I known this it would never have happened. I was away that day getting some of the welding done, in Gosport. Water got into it through a sealant leak at the 12 o clock position, the MDF swelled as it would and pushed the E forwards. This is also why I was glad to have done a soak test on the new PLA shims so know this won’t recur.

The new E was glued into place and held flush with the big clamp overnight till the glue set.

The top rh corner glue had also parted I think due to water then freezing, so that was cleaned out and glue syringed in till it flowed out of the bottom edge. This too was then clamped as you can see.

The next morning we returned, removed the clamps, did a major clean up of excess glue etc then redid the silicone sealant.

This is it now..

Now as good as it can be. There is a near invisible crack in the top part of the black granite, this is now seriously bonded to the SS backplate so should not grow. I also met with Paul Johnson the NMA grounds manager and we have implied permission that if we ever have a serious problem, I can unbolt the top bit with the brevet on it and go back to Cristofoli for a rework, seriously hope this will never be needed!

Ian Harvey – July 2023